Ohio History Journal

BLAST-FURNACES OPERATED BY THE

SEPARATIST SOCIETY OF ZOAR,

OHIO

BY E. J. BOGNAR

A most important contribution to the

success of the

Separatist Society of Zoar was iron

ore. The village

of Zoar was founded in 1817 by 300 or

more Sepa-

ratists who had embarked early that

spring from

Wurtemburg,1 Germany. The party was led

by one

Joseph M. Bimeler2 and the desire for

religious free-

dom brought them to this country where

they settled in

the inviting wooded region of the

Tuscarawas Valley.

Since the people had little or no money

and few

worldly possessions it was quite

necessary for them to

manufacture most of the things they

needed. The party

that settled here fortunately counted

in their ranks

learned craftsmen of various kinds.

Being of German

stock, they had mastered their trades

with characteristic

Teutonic thoroughness. Consequently we

find that

these people made everything that they

needed, such

as wearing apparel, machinery,

household goods, ve-

hicles and other necessaries of life. At

the height of

its prosperity the Society boasted some

12,000 acres, a

tannery, flour-mill, lime-kiln,

foundry, woolen-mill, ma-

1 Ohio Archaeological and Historical

Quarterly, Vol. VIII, July, 1899.

2 Originally Baumler, which name was

later changed to Bimeler, and

is so known today in Zoar and

elsewhere.--Ed.

(503)

|

504 Ohio Arch. and Hist. Society Publications chine shop, blacksmith shop, planing-mill, brick-yard, dairy, brewery, and bakery. Toward the end of the communistic regime even a powerhouse was claimed by the people. In fact, about the year 1883, the prosperity |

|

|

of this village was so pronounced that it drew tradesmen from Akron, which place according to Jacob Singer, was not nearly as thriving a vil- lage. The Separatists did not come here to set up a com- munistic form of govern- ment, but finding them- selves composed of young children, old people, and the able-bodied, they de- cided to band together and work for a common good. They chose as their head Joseph M. Bimeler, who proved to be a very able leader and business man. Hence, as soon as possible, |

|

the people were classified and placed where Bimeler thought they would do the most good. Some worked in the fields, others in the tannery, some in the woolen mill, etc. Each one had a certain task allotted to his or her special care. The crops were stored in large barns and the cattle kept in a large general building. All the bread was baked in the village bakery and carried around to |

|

Society of Zoar Blast-Furnaces 505 the individual homes. The beer-wagon passed around twice daily and the households could have all that they wanted. Several families commonly lived in a home and all ate well, lived simple lives, had few worries and were contented. Money there was none. Nothing be- longed to an individual but everything to the Society as a whole. From the foregoing one readily gathers that con- siderable iron was needed by the Zoarites. Inasmuch |

|

|

|

as iron ore abounded in the hillsides and was rather easy to procure, they conceived the idea of manufactur- ing their own pig iron. This leads us to our main topic, namely the blast-furnaces of Zoar. The writer has devoted considerable of his time to the study of the village of Zoar and found the problem of obtaining the past history of the Society a most difficult task, even though it disbanded as late as 1899. The greater por- tion of the members of the Separatist Society left Zoar |

|

506 Ohio Arch. and Hist. Society Publications and now but few remain. Joseph Breymaier,3 aged 69 years, is one of the oldest members left in the commu- nity. He tells us that the slag piles, the mute testimony left where the furnaces once stood, looked the same in 1869 as they do now. At that time he was nine years of age. In other words these furnaces ceased operat- ing before he was born. Mrs. Beiter, aged 82, who is the oldest living Zoarite, states that the slag pile at the |

|

|

|

Zoar furnace as far back as she can remember, has al- ways looked practically as it does now. This evidence, then, places the cessation of the furnace at no later date than 1847. There are no records of when they commenced, where the pig iron was shipped, or what the daily production was. No one even knows when the works ceased. We have appealed to the Department of Public Works of Ohio and have personally perused 3 One of the oldest living Zoarites that belonged to the Separatist So- ciety. He served as one of the three directors on the last board in 1898. |

|

Society of Zoar Blast-Furnaces 507 their early records, and all to no avail. It seems, there- fore, that the history of these most interesting furnaces has been entirely forgotten, even though they doubtless played a very important part in the life of the Sepa- ratist Society. The Ohio Canal, which was started in 1825, was open for navigation in this locality early in 1828. This event no doubt spurred the Zoarites on to take advan- |

|

|

|

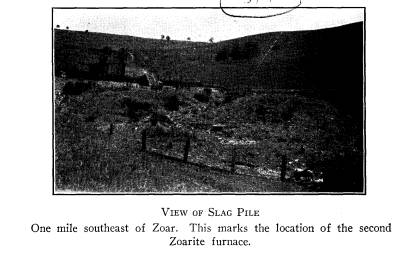

tage of the opportunity and ship their surplus. It is very likely that the second furnace, which is located one mile southwest of Zoar on the Renner farm, was built and operated for the sole purpose of shipping pig iron on the canal. The furnace site is too far from Zoar (about 6 miles) and its production of such proportion that it was out of the question to consider that the Sepa- ratists consumed its output. It was operated by the Society merely as a commercial enterprise and rewarded them handsomely for their efforts. Plate No. 3 shows |

508

Ohio Arch. and Hist. Society Publications

the blast-furnace slag pile, only half

of which remains,

the rest having been used for road

ballast. Plate No.

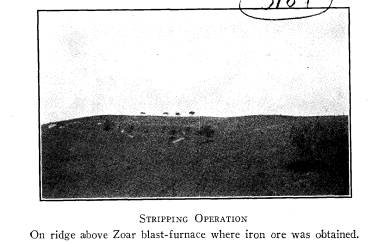

4 is a view of the diggings where iron

ore was obtained

by stripping. The trench is at least

half a mile long and

thousands of tons of over burden were

removed here.

The ore occurs in nodular form and is

associated with the

Upper Freeport Limestone of the

Allegheny formation.

A large fourteen room community dwelling-house

stood

near the furnace where lived the men

who operated the

furnace and the diggings. It seems that

teams were

used wherever possible and that only

the selection of

the uncovered ore was done by hand. The

furnace was

located at the base of the ridge shown

in Plate No. 4,

hence it was quite simple to bring the

ore to the furnace.

The furnace in turn was only about a

quarter of a mile

from the Ohio Canal. The approach

furthermore was

made easy as the wagons loaded with the

pigs descended,

by way of a gently sloping, rather wide

valley, to the

barges.

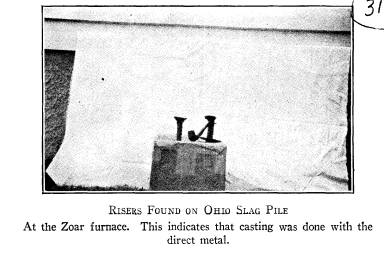

A careful scrutiny of the slag pile

rewarded the au-

thor with risers, pieces of pig iron,

bits of the limestone

flux, and revealed the fact that

charcoal was the fuel

used in the smelting of the ore. The

lining was com-

posed essentially of ganister obtained

locally in large

quantities. A very poor grade of

fire-brick was also

used. These were made of a low

refractory plastic

clay with a considerable proportion of

sand and large

particles of grog. Specimens of the

ganister and the

brick with slag adhering are in the

writer's possession.

The ganister seems to have been very

effective in re-

sisting the fluxing of the metal and

the slag.

The size of the furnace cannot be

determined as

|

Society of Zoar Blast-Furnaces 509 everything has been destroyed. Judging from the slag pile and the ore diggings, at least several thousand tons of pig iron must have been produced. The older of the two Zoarite furnaces is located on the slag road that joins Bolivar and Zoar and which passes the Imperial Fire-Brick Company and the fish hatcheries. It is about one and one-half miles north- west of the village and (essentially) on the banks of the Ohio Canal. A short spur from the main canal runs |

|

|

|

up to the site of the furnace. It is evident that from this iron furnace pits and possibly castings, were ex- ported. We have reason to believe, though, that it was this operation that supplied the needs of the commu- nity and that only the excess production was shipped away. Also it is our candid opinion that this furnace was built and put into production before the Canal, or about in 1820. Our reason for this is that the three hundred settlers had very few implements with them |

510

Ohio Arch. and Hist. Society Publications

and in order to survive they needed

nails, latches,

hinges, and such like, so it seems very

possible that the

furnace was founded even before 1820.

Later records

show that the community became famous

for its large

heating stoves, plowshares and

machinery. The iron

for all of these, we are certain, was

melted by this

furnace.

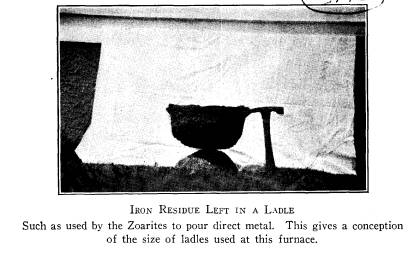

At this furnace site we found evidence

as shown in

Plate No. 5 that castings, probably

stoves, were made

of the direct molten iron with further

refining. The

ladles used are estimated to have held

several hundred

pounds of melt. Five of these ladle

bottoms were found

here. The risers (in Plate No. 6) which

were found

in the slag pile are also evidence that

casting was done.

Here, as at the Zoarville furnace just

described, ganis-

ter and a poor grade of fire-brick made

up the lining.

The fuel was charcoal and the flux the

Lower Mercer

limestone. The latter was obtained near

at hand, as

the stone outcrops near the stream

level of the Tusca-

rawas River. Later this stone was

exported in large

quantities to Dover where it was also

used as a blast-

furnace flux.

The ore used here was probably of two

different

grades. First, the kidney ore obtained

at the Upper

Mercer level was used. Perhaps the kind

more com-

monly smelted was that obtained in the

shale between

the No. 5 and the 5-A coals. Numerous

diggings scat-

tered about the hillside were found at

both horizons.

As the pits on the upper level are the

larger and by far

the more common, we believe most of the

ore to have

been mined at this level. None of the

mining was un-

derground, all being dug out of shallow

pits. Both

|

Society of Zoar Blast-Furnaces 511 ores used are of the kidney variety, the average iron content being between 28 and 34 per cent. The ore beds are not rich near this furnace and for this reason, only the easily obtained iron nodules were dug. This accounts for the numerous pits of varying size to be found in the adjoining hillsides. The Upper Freeport horizon does not exist here and only makes its appear.- |

|

|

|

ance several miles to the southeast. It was probably after the obtaining of ore had become a problem that the Zoarites discovered the richer horizon at Zoarville. They no doubt decided it was much easier to build a furnace and do the smelting there than to transport the ore to the Zoar furnace. This leads us to believe that the Zoarville furnace was the larger and more sys- tematically operated of the two. Plate No. 7 displays a cast iron wheel which no doubt was made in their foundry. This, however, only |

|

512 Ohio Arch. and Hist. Society Publications came into being some time after 1870, as the old resi- dents remember about this. These furnaces ceased operation shortly after the advent of the Lake Superior iron or three-quarters of a century ago. The Separatists were wise people and when they surmised that they could not compete with iron made from Lake Superior ore, they abandoned their operations, built a foundry and bought pig iron. |

|

|

|

The dissolution of the Separatist Society of Zoar was brought about by events just such as this. In 1899 they finally realized that they could no longer successfully compete with the industries outside their community. There crept into the quiet settlement discontent caused by outside influences and the ever increasing influx of tourists and vacationists who came here in the summer months. The younger generation felt that they did not have the opportunity for advancement as did the youth of the outside world. They wanted money and a |

|

Society of Zoar Blast-Furnaces 513 division of property. In other words they were dis- satisfied with the communistic form of government which had worked so well for their fathers and grand- fathers. The disbanding came in 1899 and today the community is a mere shadow of its former self. The population is about 250; most of the old settlers have departed and antique-hunters have stripped the place |

|

|

|

of the old home-made things. So well has this been accomplished that it is with difficulty one finds genuine things made by the Zoarites. The old villagers seem to place little value on the things left by their parents. Practically anything still remaining can be purchased. What seems the worst of all is that very few records are available. Those that were kept have become scat- tered and this together with the fact that only a few old Separatists survive, makes it exceedingly difficult to gather reliable information about the most successful and longest-lived communistic society in America. Vol. XXXIX--33. |