Ohio History Journal

AN ECONOMIC HISTORY OF THE JACKSON

COUNTY IRON INDUSTRY

A THESIS PRESENTED FOR THE

DEGREE OF MASTER OF ARTS

BY VERNON DAVID KEELER, A.B., LL.B.

INTRODUCTION

"The Cyclops here their heavy

hammers deal;

Loud strokes, and hissings of tormented

steel

Are heard around; the boiling waters

roar;

And smoky flames through fuming tunnels

soar."

--Vergil.

In early Biblical times, according to

the fourth chap-

ter of Genesis, "Tubal Cain,"

born in the seventh gen-

eration of Adam, was an

"Instructor of every artificer

in brass and iron." The slow

development of iron mak-

ing among the early Greeks, Hebrews,

and other early

peoples is well known to the economic

historian. There

is much evidence to prove that the Assyrians,

Chaldeans

and Babylonians were acquainted with

its manufacture.

Prof. J. Russell Smith, in The Story

of Iron and

Steel, states:

The primitive methods of the ancient

world finally focused

themselves so far as the Mediterranean

basin and European

countries are concerned, upon the so-called Catalan

forge, first

devised and used in Cataline, Spain.

This differs but little from

the ordinary blacksmith's forge, which

has the air blast furnished

by a bellows, or if possible by a

waterfall, through the device

known as the "Trompe." This consists in

letting the water fall

(133)

134 Ohio Arch. and Hist. Society Publications

through a pipe, carrying with it bubbles

of air, which escaped at

the bottom of the pipe with an air-tight

receptacle. There the

accumulated air has a pressure derived

in being carried down-

ward in the falling water. The Germans

by a series of slow

improvements evolved the first form of

blast-furnace. This was

called by the Germans the

"Stuckofen," being built to a height

of ten to, sixteen feet, and having an

output of from one hundred

to one hundred and fifty tons a year in

its best form.

Many variations and improvements

followed the

German improvements, before the making

of iron was

introduced into the United States,

which occurred in

Massachusetts in 1645. Then by degrees,

tediously

but surely, its manufacture spread

throughout the colo-

nies, chiefly because of necessity.

When Washington became President, iron

was made

to some extent in practically every

state of the newly

formed union. Proof that the use of

iron was known

before the white man's coming is shown

by the fol-

lowing quotation from the History of

Iron in All Ages,

by James M. Swank:

Professor Putnam, the archaeologist, of

Harvard University,

found in the ancient mounds of Ohio

masses of meteoritic iron

and various implements and ornaments made by hammering

the

pieces of meteoritic iron. This native

iron the ancient people

used the same as they did native silver

or native gold, simply as

a malleable metal. It was only after

contact with Europeans

that the Indians obtained iron in

different forms, and in due

time learned to heat and shape it as a

blacksmith would do.

In the Smithsonian Institution at

Washington may

be seen a replica of the early iron

mine, showing an

American Indian woman carrying a basket

of the pre-

cious iron ore from a tunnel, which

extended straight-

ways into the earth.

Although backed by the experience of

their fore-

runners, the iron makers of Ohio needed

unlimited

Introduction 135

courage, strength of will, and

perseverance to "carry

on." The development of the

Southeastern Ohio Iron

Region at the beginning of the 19th

century, gives to

the section an unusual romantic story

for the economic

historian. This region, which developed

from such a

small beginning, later rivalled such

regions as Toledo,

Spain, and the famous iron region of

Asia Minor.

The Hanging Rock Iron Region furnished

crude iron

for use in making ordnance in England

during the

Crimean War, and it was highly praised

by their chem-

ists. During the Civil War, the Hanging

Rock iron

was again in great demand, and the

region furnished

the materials for building the famous

Merrimac, the

iron-clad ship which won fame in the

historic duel with

the Monitor. One of the Hanging Rock

furnaces fur-

nished the pig iron which was used in

moulding the

famous "Swamp Angel" cannon

used in the defense of

Charleston Harbor. The Hanging Rock

iron was so

much in demand during the Civil War,

that ofttimes

the iron was started on its journey to

the railroad in

wagons, before being allowed to cool,

and many wagon

beds were burned. On the industrial

side the iron be-

came equally famous for its casting

qualities; it being

much in demand in Cincinnati, St.

Louis, Pittsburgh,

and other foundry and steel centers.

Iron as we know it now is a basic

material, the prices

being used as an economic barometer,

especially during

a period of depression, like that

through which we

are now passing. The dependence of

manufacturing

upon iron and steel is taken for

granted. If a

country be lacking in iron and its

close ally, coal, it is

indeed in poor straits to become a

commercial or indus-

136

Ohio Arch. and Hist. Society Publications

trial nation, unless transportation is

so well developed

that the necessary materials may be

secured easily, or

at small cost.

The counties which comprise the Hanging

Rock Iron

Region of Ohio seem to have been

blessed with a plente-

ous supply of iron ore and coal, and

the necessary

limestone is also found in great

abundance.

The purpose of this thesis is to give a

glimpse of

this most interesting and historical

region. For this

purpose Jackson County has been chosen

from the

group involved, to serve as a

representative area for

study. The development of the iron

industry in this

region, beginning with the

establishment of the first

furnace in 1811, will be closely

studied. The effect of

the iron industry upon the entire

region will be given

cognizance, including the growth of

markets and com-

mercial centers. Concentrating the

study, the develop-

ment of each furnace in Jackson County

will be noted,

from the beginning of the industry in

that county in

1836, and continuing to the present

time; hence the story

of the struggle between the three major

fuels, coal,

charcoal and coke.

The author is indebted to the following

persons for

furnishing valuable information and

help, that this story

may be complete: Mr. H. H. Maynard,

professor of

marketing, Ohio State University, who

suggested this

theme, and has carefully followed the

preparation of it;

Mr. Ray B. Westerfield, professor of

political economy,

Yale University; Mr. Wilbur E. Stout,

State geologist,

Columbus, Ohio; Mr. Robert Jenkins,

County auditor

for Jackson County; Mr. Joseph J.

Jones, last manager

of Jefferson Furnace, Oak Hill, Ohio;

Mr. Andrew J.

Introduction 137

Dutiel, last manager of Madison

Furnace, Jackson,

Ohio; Mrs. Eliza Bundy Wells, daughter

of Hon. H.

S. Bundy, and wife of Harvey Wells,

builder of the

city of Wellston; Mr. C. B. Galbreath,

secretary of the

Ohio State Archaeological and

Historical Society, Co-

lumbus, Ohio; Mr. John E. Jones,

present owner and

president of the Globe Iron Company, of

Jackson, Ohio;

Mr. John S. Sylvester, editor of the

Wellston Telegram,

Wellston, Ohio, and Mr. S. J. Newell,

of the Jackson

Herald.

Information and help have been drawn

from so many

sources that to acknowledge them all

would require

too much space. In addition to the

above, thanks are

due to the older residents in Jackson

County, who

worked in the iron industry, many of

whom generously

gave much valuable data and

information.

VERNON D. KEELER.

Jackson, Ohio, December 22, 1931.

CHAPTER I

THE HANGING ROCK IRON REGION

The name which is used to designate this

most inter-

esting and once most important iron

making region in

the United States, is obtained from a

cliff, located on

the brink of the Ohio River. This

location was made

famous by the old Hanging Rock Forge,

which was so

well described by Dr. Hildreth, and is

worthy of re-

production here:

Four miles above the mouth of the Little

Sandy on, the Ohio

side or right bank of the Ohio River,

and in the midst of the iron

region, is a celebrated cliff of

sandstone, called the "Hanging

Rock." The upper portion of the

cliff, which is nearly four

hundred feet high, projects over the

mural face of the rock like

a cornice of a house. The Ohio flows

close to its base, while

beneath and under its projecting walls,

is erected a forge, for

the refining of iron. The blast of its

immense bellows, and the

thundering noise of its immense hammer,

weighing more than a

ton, echoing and reverberating under the

walls of the cliff, afford

no inapt emblem of the labors of

Cyclops, under the caverns of

Mt. Etna. An abundance of iron ore is

found in the vicinity,

and a few miles back in the hills a

furnace called the "Aetna,"

furnishes the pigs for the anvils of the

modern Cyclops. Bar

iron of an excellent quality is

manufactured at this most inter-

esting spot.1

The nucleus of this most famous region

is found in

the four counties of Jackson, Lawrence,

Scioto, and

Vinton, with minor plants in Hocking

and Gallia Coun-

ties in Ohio; and Greenup, Boyd,

Carter, and Lawrence

Counties in Kentucky, embracing in all

about two

thousand square miles. Considering the

whole of the

1 History of the Hanging Rock Iron Region. of Ohio, v. I, pp.

266-268.

(139)

140 Ohio Arch. and Hist. Society Publications

above-mentioned region, a famous

historian has written

that "It is doubtful if any

similar section of the middle

west can furnish so much picturesque

detail of human

experience and enterprise."2

The Hanging Rock Region is bounded on

the east

by the Ohio River, and on the west by

the Scioto River

and its tributaries. The region had a

seemingly in

exhaustible supply of iron ore, a

splendid grade of lime-

stone to be used for flux, and plenty

of timber-land to

be used in making charcoal. The

existence of men who

were willing to take long chances upon

industrial ven-

tures, made possible the growth of this

region, which

was practically an unknown wilderness

previous to 1800.

The following quotation will show the

abundance of

ores in the Hanging Rock Region at the

beginning of

the nineteenth century:

The limestone ores, as calcareous and

argillaceous carbonates,

and hydro-peroxides, or limonites, are

very abundant and have

been mined for years in the Hanging Rock

regions of Ohio and

Kentucky. They were the base of the

charcoal industry of this

famous region. . . . The limestone ores

derive their name from

being associated with a thick and

extensive deposit of grey lime-

stone. . . . The iron made from this ore

has always held a front

rank in market, the cold blast iron

being particularly prized for the

manufacture of ordnance, car wheels, and

other castings requir-

ing tough iron. The counties

constituting the Hanging Rock

Iron Region, on both sides of the Ohio

River along the horizon

of the grey limestone ore, have been

worked over in every hill,

and the ore stripped to a depth of eight

to twelve feet, forming a

line of many miles of terrace work.3

The making of charcoal was an expensive

procedure,

in spite of the fact that timber-land

was plentiful. The

2 A Standard History of the Hanging Rock Iron Region of

Ohio. Pre-

face. E. B. Willard, editor.

3 Historical Collections of Ohio, edited by Henry Howe, Columbus,

Ohio. 1896, v. I, p. 117.

The Jackson County Iron

Industry 141

numerous charcoal pits scattered about

over these

southern Ohio counties, still form a

fitting memorial to

this industry of bygone days. After the

charcoal was

manufactured at the kiln, mule teams or

oxen were used

to transport it to the furnace grounds.

A two-hundred-

bushel load of charcoal was usually

drawn by four yoke

of oxen or by four-mule teams. In many

instances

the coal had to be hauled a great

distance to the fur-

nace bank. It was generally figured

that five cords of

wood should coal one load of charcoal,

which was two

hundred bushels. This charcoal was used

as fuel in

all the old furnaces of the Hanging

Rock Region, and

hence the charcoal industry was at one

time the lead-

ing branch of the iron making venture.

Perhaps the greatest factor in the

transportation

field during the first part of the

nineteenth century,

was the historic and beautiful "La

Belle Riviere" (Ohio

or Beautiful River), so named by the

French following

its discovery by La Salle in 1669, this

nation having

exercised control of it until 1763.

A model of one of the Ohio River

flatboats which

plied the waters in these early days

may be seen at the

present time in the United States

National Museum at

Washington, D. C. The keel-boat used

prior to the

steamboat, was used for the

transportation of flour and

other products from Cincinnati to

northern points. The

old-fashioned flat-bottom boat

descended the Ohio and

Mississippi Rivers, with cargoes of

iron, and other

materials, as soon as production was

begun in the in-

land Ohio towns, thus opening a

veritable road of com-

merce between north and south, east and

west.

The first Ohio River steamboat was

built in Pitts-

142 Ohio Arch. and Hist. Society Publications

burgh in 1810-1811. It was 138 feet

long, and of 300-

ton burden. The following description of this boat is

of particular interest:

The New Orleans left Pittsburgh

in October, 1811, and

created a veritable sensation all along

the river--panic and con-

sternation in some places which advance

information had not

reached. "A novel sight,"

wrote one contemporary journalist,

"and as pleasing as novel to see a

huge boat working her way

without the appearance of sail, or pole or any manual

labor about

her--moving within the secrets of her

own mechanism, and pro-

pelled by power undiscoverable."4

The continued growth of this

magnificent avenue of

traffic is a matter of history, and

shows us the immense

value and importance of water traffic,

especially during

the days of the pioneer, when every

effort was made to

use the available resources at hand.

In order to reach this line of traffic,

it was necessary

to use the familiar pack-horse, and

still later the ox

cart, which used roads little better

than paths through

the dense vegetation of the region. The

roads, in many

instances, followed the creek beds

where the water was

shallow, and furnished a suitable foundation

for travel.

Nothing that could be called roads

existed in the

territory west of Pittsburgh at the

beginning of the

nineteenth century. Pittsburgh was the

assembling

point for many a trader's boat or

pack-train closely fol-

lowing the settlements in the Hanging

Rock Region at

the beginning of the century. The

pioneer families

were of the usual adventurous, poor but

hardy group,

familiar in all frontiers in early

days. There were only

a few persons of wealth among them, but

such as they

4 The Ohio River in History.--Harry Pence.

Pub. by Ohio Valley Im-

provement Association, Cincinnati, Ohio,

1929, p. 17.

The Jackson County Iron

Industry 143

were, they formed a nucleus around

which might be

built an industrial enterprise.

Because of necessity the familiar

country cross-roads

store soon came into existence, these

serving as markets,

places of social enjoyment,

post-offices and general

utility centers; the stores carrying

only articles of neces-

sity, such as hats, caps, flour or

corn-meal, women's

clothing, articles of dress for young

and old, implements

of labor for the charcoal and iron-workers,

and general

supplies for the sturdy pioneer.

The blacksmith shop was generally

considered a

necessary adjunct to the general store

in most of the

small hamlets, and it occupied quite a

place in the com-

munity life. The settlers in need of

iron implements

depended upon the distant regions of

Pennsylvania, or

other iron regions, to supply their

wants. Little did

they realize that underneath the soil

in these Ohio coun-

ties, lay untold wealth in the untouched

ores, and in the

abundant allied products.

Iron was sorely needed for the

manufacture of the

needed implements of labor, and for

pots, pans and

kitchen utensils. The blacksmith shops

at Portsmouth,

Hanging Rock, Chillicothe, Piketon

(having a name as

early as 1814), and Jackson (officially

organized in

1816), all did a rushing business. Bar

iron often was

brought over the Appalachian mountains

by means of

pack-horses, the iron being bent over

the horse's back,

so as to allow different articles of

merchandise to be

tied to both ends of the bar.

The cities of Pittsburgh, Cincinnati,

and New

Orleans were the pioneer's chief buying

centers at the

beginning of the nineteenth century.

Slowly it dawned

144 Ohio Arch. and Hist. Society Publications

upon the settlers that they must secure

some commodity

which could be easily exchanged for

their necessities,

if they would maintain their trade. The

following

quotation sheds interesting light upon

the first iron

venture in southern Ohio, at the

beginning of the cen-

tury:

Previous to the first smelting of iron

in the Hanging Rock

Region, Brush Creek Furnace in Adams

County, the first erected

in the State of Ohio, was in blast in 1811. It was

built by

Ellison, James and Colonel Paull. . . .

This was also the first fur-

nace in the United States run by steam,

the engine which operated

it, was built by the Pittsburgh Steam

Engine Co. who, sent James

Rodgers to install it.5

Thus we had the beginning of the

venture which was

destined to make its impression upon

the entire section,

where such an abundance of raw

materials remained

untouched. Cheap labor was found in the

incoming

pioneer, who was willing to cut the

wood at twenty-five

cents a cord, with other labor

receiving a proportionate

compensation. Little capital was

necessary in the con-

struction of the first furnaces, as

they were of the

crudest type.

The second venture in the iron industry

was under-

taken some seven years later, across

the Ohio River in

our neighboring state of Kentucky. In

the year 1815,

there lived a gentleman by the name of

Richard Deer-

ing; "quite above the average of

his class and day, for

enterprise and investigation, and he

was also consider-

able of a mechanic."6 Mr. Deering

engaged in salt

boiling as a vocation, and accidentally

discovered the

iron ore located on his lands. Having

made iron in his

5 B. Willard. Op. cit., Vol. I,

p. 269.

6 E.

B. Willard, op. cit., Vol. I, p. 268.

The Jackson County Iron Industry 145

native state of Pennsylvania, he

decided to make some

of this ore into pigs. Meeting with success in his small

cupola he engaged about half a dozen

moulders to run

the material into hollow-ware.

The success of that crude attempt

induced Mr. Deering, in

1818, to form a partnership with David

and John Trimble for

the erection of "Argillite"

furnace, the first iron plant to be

established in the Hanging Rock Region.

It was located in

Greenup County, Kentucky, six miles

southwest of Greenups-

burg, upon the left bank of Little Sandy

River. The stack, 25

feet high, six feet "bosh,"

was cut solid in a cliff of black slate--

hence the name

"Argillite"--with only two sides for arches. A

dam thrown diagonally across the river

with a massive undershot

water-wheel, furnished power for the

blast. The iron produced

was made into hollow-ware on week-days,

and run into pigs on

Sundays. The blast-cylinder and

water-wheel were made by

John Deering, whom his brother had

engaged for that purpose.

The original capacity of the

"Argillite" was one ton daily, it

being classified as a

"cold-blast" furnace.7

The task of finding a market for the

surplus iron

was not a difficult one, as it was easily

loaded on rafts,

and floated to Cincinnati, Portsmouth,

and other river

cities. The iron being disposed of, the

lumber was sold,

and the men took the first steamer back

home.

After Mr. Rodgers completed his work

for the

Pittsburgh Steam Engine Company at the

Brush Creek

Furnace, he became very much interested

in the pos-

sibilities of the surrounding region.

As a result of this

interest the first iron furnace north

of the Ohio River

in the Hanging Rock Region was

established in 1826.

Mr. Rodgers had as partners in this

enterprise Colonel

John Means, Valentine Fear, Mr. Sparks,

and Mr.

Thomas W. Means, the latter becoming

prominently

identified with many furnaces during a

later time. The

7 Ibid, p. 268.

Vol. XLII--10

146 Ohio Arch. and Hist. Society Publications

new furnace was named the

"Union," and it was very

similar in construction to the Brush

Creek Furnace,

turning out about the same amount of

iron, from three

to four tons a day.

Mr. Henry Howe, who visited this region

in 1884,

wrote the following concerning Union

Furnace:

Union Furnace was the first iron furnace

north of the Ohio,

in the Hanging Rock District, built in

1826. In 1837, John

Means, a son of Thomas W. Means, leased

it, at first making

three to four tons a day, and soon

increasing the output to thirty

tons a week, considered unusual.

Mr. Means stated as follows: "When

I leased Union Furnace

in 1837, corn sold for 12 1/2 cents a

bushel, and wheat for from

24 to 26 cents. Wages for competent

laborers were only $10.00

a month. I made a trip to New Orleans

and saw wheat sold

there for a quarter of a dollar a

bushel; and corn on the cob, at

the same price per barrel. We saw no

gold, and little silver coin,

except in small pieces; our circulation

was chiefly bills of state

banks, and those were continually

breaking."8

"Union" was located only four

miles from the Hang-

ing Rock Forge and thus served as a

splendid feeder

for its immense hammer. Closely

following the success

of "Union," furnaces began to

spring up throughout

the Hanging Rock Iron Region, and it

was soon on its

way to fame. One of these furnaces,

"Hecla," which

was established in 1833, is shown on

page 147.

The following figures give one somewhat

of an idea

as to the materials used at one of

these early furnaces

during a blast:

Clinton Furnace, located in the Hanging

Rock Region, used

the following materials in a blast of

204 days in 1836: Charcoal,

307,876 bushels . . . Stone Coal, 30,277 bushels . . . Limestone,

260 tons . . . Iron Ore, 2,546 tons . .

. Pigs made, 896 tons.

Average quantity per day, 4 tons, 7

cwt., 3 qrs., 10 lbs. Average

stock being: 1,509 bushels bituminous

coal, 148 bushels charcoal,

8 Henry Howe, op cit., 1896, Vol.

II, p. 62.

|

The Jackson County Iron Industry 147 Iron Ore 12 tons, 9 cwt., 2 qrs., 12 lbs. Limestone, I ton, 7 cwt., 1 qr., 22 lbs.9 The charcoal iron produced at these furnaces had many and varied uses. Superior ores were needed, for the purer the raw materials, the more valuable the fin- ished product. Strength and uniformity are required in making the best iron, and these qualities were secured through the use of charcoal fuel, and the exercise of care in choosing the better grades of ore. The chief |

|

|

|

use of the charcoal iron was for foundry purposes, where it was moulded into all types of castings, in the various Ohio River cities. The greatest handicap of the pioneers was a lack of working capital, outside of the transportation problem, which presented itself at every turn. As the laborers were paid only $10.00 a month, and the other wages and prices in line, it is not 9 Report of Caleb Briggs, assistant geologist of Ohio, 1836. Geological Survey Report of 1869, given by Prof. J. S. Newberry, files of State Geo- logist. |

148 Ohio Arch. and Hist. Society Publications

to be expected that any considerable

savings would be

possible.

A progressive movement which proved a

blessing

for the industry for a time was the

building of the Ohio

Canal in 1831-32, at a cost of

$5,000,000. This canal

extended from Cleveland to Portsmouth,

a distance of

307 miles, and opened up a new line of

trade for the

entire region. This canal was of great

aid in bringing

machinery and equipment from the Great

Lakes region,

and helped to overcome the handicap of

lack of transpor-

tation. However, the later results did

not bear out the

wishes and hopes of its promoters, as

shown by the fol-

lowing quotation:

In January, 1838, navigation was closed,

and twice in the

spring of 1839 the canal was closed for

repairs, goods being

brought to Brush Creek and wagoned to

Portsmouth. . . . To give

an idea of the canal as a revenue

producer, it may be said that

the tolls for 1837 amounted to $433,699,

and $382,135 for 1838;

expenses for repairs in the latter year

being $214,581. In July,

1855, the newspapers announced that the

canal was in a deplor-

able condition, though in March, 1858

there were tri-weekly

packet lines from Portsmouth to

Columbus. By 1860 railroad

competition had had its effect, and the

canal tolls had materially

decreased, as witness the following

figures: for the quarter end-

ing February 15, 186o, $7,150; and for

quarter ending May 15,

$10,568.10

Relying chiefly upon the new markets

made avail-

able by the Ohio Canal, several new

industries were

begun in Portsmouth, the nucleus of the

Hanging Rock

Region. Perhaps the greatest and most

important of

these industries was the Portsmouth

Iron and Steel

Company, founded in 1831, it being the

first plant of its

kind west of Wheeling, West Virginia.

The president

10 E. B. Willard, op. cit., Vol.

I, pp. 92-93.

The Jackson Counter Iron

Industry 149

of this company was John P. Terry, who

owned several

charcoal furnaces, and thus made direct

use of the pig

iron produced. Their products were bar

iron, sheet-

iron, nails, and like materials. At a

later time they

manufactured all kinds of steel,

spikes, "T" rails,

specializing in iron boiler-plates and

boiler rivets. By

the year 1885, their annual product was

valued at about

$700,000 per year, thus being a factor

of great import-

ance to the nearby furnaces.

In 1837 a new era dawned upon the iron

business in the

Hanging Rock Iron Region and of the

country, caused by the

introduction of the hot blast. Three or

four furnace men met

at Vesuvius and there agreed that they

would test the principle;

that they would employ a man to put up a

hot blast at Vesuvius,

and if it proved satisfactory, Hurd,

Gould and Co. were to pay

all expenses; if a failure, the expense

was to be divided among

all the parties to the experiment. The

result was so successful

as to mark a great step in the progress

of the industry. William

Firmstone was the man selected to

install the hot blast--the first

it is believed in the United States.11

Thus we note that during the short term

of a quarter

of a century, the iron industry of

southeastern Ohio was

becoming well established; it being

stated by a good

authority that Thomas W. Means, who

kindled the first

fire at the Union Furnace, lived to see

over fifty fur-

naces in operation throughout the

entire region.

To determine the relative importance of

the Hang-

ing Rock Region with other regions of

the United

States, the following figures are of

particular interest:

The first record of the amount of iron

made, according to

the U. S. Association of Charcoal

Iron-Workers, in its journal

for 1880-81, is in 1810, when there were

in existence in this

country 153 charcoal furnaces, 135

bloomeries, 330 forges, and

34 rolling and slitting mills, producing

53,908 gross tons of pig

iron, and 36,385 tons of blooms,

billets, and bars. In 1840 the

11 Ibid, p. 270.

150 Ohio Arch. and Hist.

Society Publications

number had been increased to 804

furnaces, producing 286,903

gross tons of cast iron, and 795 forges,

bloomeries and rolling

mills.

The Geological Survey of 1869 stated

that 38 fur-

naces were in operation in the entire

Hanging Rock

Region. These furnaces produced about

90,000 tons of

charcoal iron, and in addition there

were five bituminous

coal furnaces which produced 16,000

tons, making a

grand total of 106,000 tons. Thus it is to be noted

that the region was gradually assuming

a leadership in

the iron industry, which it was to

develop for many

years to come.

CHAPTER II

BEGINNING OF THE CHARCOAL EPOCH IN

JACKSON COUNTY

"Ay me, what perils do environ,

The man that meddles with cold

iron."

Jackson County is an upland county,

lying at the

head of the waters. The loftiest hills

are in Washing-

ton and Jackson Townships, with a few

points in Lib-

erty Township reaching 1,000 feet. The

county is

bounded on the north by Vinton, on the

east by parts of

Vinton and Gallia Counties, on the

south by Gallia and

Scioto, and on the west by portions of

Scioto, Pike and

Ross Counties. There are numerous hills

and dales,

formed by the waters of the melting

glaciers many cen-

turies ago. Two means of water

transportation were

seemingly available for industrial

development, when

the idea was first projected. The

Scioto River was

some distance to the west, and Raccoon

Creek was on

the east. As we shall see, however,

both of these

routes proved to be impracticable.

The existence of the salt-licks in

Jackson County

accounts for its early settlement, the

pioneers coming

from many distant places to secure this

needed ingre-

dient. It is known that licensed

fur-traders began to

visit the salt-licks about 1720, and

that they found evi-

dence of habitation at that time.

"An edition of a map

by Lewis Evans, the Welsh geographer,

published in

(151)

152

Ohio Arch. and Hist. Society Publications

1755, including Virginia, and the Ohio

Valley, had the

Scioto Salt Licks marked on it."12

Transportation facilities were indeed

lacking at this

early date, but the need for salt

caused many emigrants

to settle at the springs, to aid in

carrying on the indus-

try. Money was scarce, and was not

often seen among

the settlers. It is stated that the

warehouses (such as

they were) at the springs were often a

type of museum,

because of the various articles brought

in exchange

for salt. Any article ranging from a

pocket-knife to a

saddle was acceptable as barter, and

even fire-water was

brought in exchange for salt. Perhaps

the best medium

of exchange was the pelt or hide, which

was in great

demand. A historian of the region

stated that "Even

some tax-collectors and postmasters

were known to take

peltries, and exchange them for money

required by the

government."13

There were two or three well-known

trails or roads

leading into Jackson, at the beginning

of the nineteenth

century. One of these trails extended

from Portsmouth

on the Ohio River, another from

Chillicothe via Jack-

son to Gallipolis. Relative to the

early road legislation,

we have the following interesting note:

"The Ohio Legislature appropriated

the sum of $800.00 on

February 18, 1804, for the purpose of

opening and making a road

from Gallipolis, in the county of

Gallia, to Chillicothe."14

The above-mentioned road was the first

road estab-

lished in the territory now including

Jackson County.

The county was organized in March,

1816, its area

12 History of Jackson County, D. W. Williams, pp. 34-36.

13 E. B. Willard, op. cit., Vol.

I, p. 87.

14 D.

W. Williams, op. cit., p. 80.

The Jackson County Iron

Industry 153

being about 410 square miles. At this

time the salt

boilers naturally held sway in every

political, social and

industrial venture.

Statistics show that the population of

the county in

1820 was 3,842, and in 1830 it had

risen to 5,941. The

year 1823 saw the first venture of the

traders in extend-

ing their operations beyond the county

boundaries.

During that year they mined more coal

than was needed

in their salt furnaces, and hauled the

surplus to the

blacksmiths of Pike and Scioto

Counties. Thus began

a development of commercial

relationships with the ad-

joining counties.

As a result of better salt brine being

found on the

Kanawha River in West Virginia, in

1826, the salt

works in Jackson County were abandoned,

the school

lands were sold, and a general revival

begun. The

school lands were appraised at from

twelve to eighty-

seven cents an acre, the average amount

being about

fifty cents. Little did the appraisers

realize that under-

neath the apparently worthless

timber-land lay untold

wealth in iron ore, coal and limestone,

all intertwined

in their usefulness. The land in

Hamilton Township,

which was to be honored by having the

first iron fur-

nace established within its boundaries,

was valued at

only twenty-five cents an acre.

The ore deposits in the southern end of

the county

were known to the furnace men of

Lawrence and

Scioto Counties, but the problem of

bringing the finished

product a distance of twenty miles made

quite a handi-

cap. The yield of from 325 to 350 acres

of timber-

land, or about 13,000 cords of wood,

were required per

year for the operation of a furnace.

The prospect of

|

154 Ohio Arch. and Hist. Society Publications cheap land, in the vicinity of rich ore deposits, caused Mr. Jacob Hurd, Mr. Rodgers, Jacob Ricker, ct al, to incor- porate a company in 1836 for the purpose of erecting the first furnace in Jackson County. All of these gen- tlemen had been engaged in the iron business in Law- rence and Scioto Counties. "This was the commence- ment of the iron industry in the county, and the engine used to blow the bellows was the first steam-engine that was ever operated in the county."15 The furnace was incorporated under the name of Rodgers, Hurd & Company, by special act of the Legis- lature. A photograph of the furnace is reproduced below. |

|

|

|

The first manager was the well-known J. M. G. Smith; Mr. Hurd was clerk, and Mr. J. H. Ricker was 15 History of Lower Scioto Valley.--Inter Cities Press, Chicago, 1885, pp. 495-496. |

The Jackson County Iron

Industry 155

storekeeper. The latter position was

one of great im-

portance, as it was at the company

store that all business

of the community was transacted. The

furnace em-

ployees were all paid in scrip, and

this was taken to the

store in exchange for various

commodities. Very often

huge profits were exacted, one

storekeeper stating that

75 to 100% was expected as a fair

return.

Although the hot blast had been proven

successful,

Jackson Furnace used a cold blast, the

product being

used in foundries which desired the

highest quality

charcoal iron. The crude method of

manufacturing

employed in the beginning, is

responsible for the low

output, about three or four tons a day.

It was of high

quality, and was much in demand. The

pigs were

hauled to Portsmouth, the nucleus of

the region, where

is was loaded on boats and taken to

Cincinnati, provided

that it was not needed for the mills in

Portsmouth. It

is regrettable that the financial crash

came so suddenly

at the time when Jackson Furnace was

just getting a

start. The following quotation will

show the conditions

which soon became general:

Property shrank to such low value, that

many people were in

doubt as to whether they possessed

anything except their lives

and their families The wildcat banks rapidly climbed the golden

stairs, and their assets went

glimmering. The necessities were

cheap, and those who suffered most in

those days were of the class

called "wealthy," excepting

perhaps, the managers of the wildcat

banks spoken of above. Neither the

farmer nor the mechanic of

the West had little to complain of.

Their wants were few and

supplies cheap. The collapse which began

about 1837, hovered

over the land as late as 1842.16

"There was a six-foot bed of ore

found along the

ridge above Jackson Furnace which

yielded 10,000 tons

16 E. B. Willard, op. cit., Vol.

I, p. 82.

156 Ohio Arch. and Hist. Society Publications

to the acre."17 In spite of the

advantages of plentiful

supplies, etc., the furnace was sold in

1840 to the firm of

Ellison, Tewksberry & Co. This

group had operated

other furnaces previous to their new

venture, and began

with high hopes of success, which hopes

were well borne

out.

During the year 1837, one of the most

scholarly

gentlemen who ever lived in Jackson

County took up

his abode in Jackson, and soon began to

exercise a tre-

mendous influence. Of this individual

Mr. Howe writes

as follows:

William Williams Mather, LL.D., a

descendant of the family

of Cotton and Increase Mather, in

August, 1836, resigned from

the army to take part in the Geological

Survey of N. Y., and in

1837 came to Ohio to superintend the

first Geological Survey of

Ohio. After the suspension of the Ohio

Survey, he purchased a

tract of 1,500 acres,

including the Pigeon Roost north of the

Court House in Jackson County, on which

he built a house and

became a citizen of Ohio.18

Professor Mather, assisted by Caleb

Briggs in the

Survey, noted the abundance of

materials for the manu-

facture of iron in Ohio, and decided to

take advantage

of the opportunity. Although his

efforts were somewhat

unsuccessful, it had its effect in

drawing attention to the

region. One of Mather's enterprises is

well described

in the following paragraph:

William Williams Mather associated

himself with a number

of capitalists and organized the

"Ohio Iron Manufacturing Com-

pany," to manufacture iron, glass,

pottery, and fire-brick, make

salt and saw marble. The company was

incorporated on March

6, 1845, with a capital of $300,000. It

was authorized to build

. . . furnaces in Athens, Gallia,

Lawrence and Scioto Counties.

This brilliant scheme never

materialized, although Mather and a

17 History of the Lower Scioto Valley, p. 496.

18 Henry

Howe, op. cit., 1896, Vol. I, p. 957.

The Jackson County Iron Industry 157

company built the Oak Ridge Furnace in

Lawrence County, but it

called the attention of capitalists to

the resources here. Mather

was more of a student than a business

man, and succeeded better

as professor at Marietta and Ohio

University.19

Had Professor Mather and his New

England

friends been able to convince the

capitalists of the pos-

sibilities of the county, the

development would have

been more rapid. When Mather examined

the coal in

1837, he pronounced it to be of the

highest quality, and

it was used to fire the boilers at

Jackson Furnace.

As to the quality of the iron being

produced in these

first Hanging Rock furnaces, Mr. Howe

stated in his

notes of 1846 that "It stood very

high for casting, and

was equal to Scotch pig for foundry

purposes."20 Mr.

Howe further stated that the iron was

excellent for bar

iron; the principal markets being

Pittsburgh and Cin-

cinnati. At this date (1846) the four

counties of

Jackson, Lawrence, Scioto, and Greenup,

Kentucky,

made about 37,450 tons annually, which

at $30.00 a ton,

the current market price, amounted to

$1,123,500.

"There were 21 furnaces in the

Hanging Rock Iron

Region. . . . Each of the furnaces employed

on an

average of 70 yoke of oxen, 100 hands,

sustained 500

persons, consumed 560 barrels of flour,

1,000 bushels

of corn meal, 10,000 bushels of corn,

50,000 pounds of

bacon, 20,000 pounds of beef, 1,500

bushels of potatoes,

besides other provisions, and tea,

sugar and coffee in

proportion."21

The coming of winter found hundreds of

wood-

choppers emigrating from their mountain

homes in

19 D. W. Williams, op. cit., p.

168.

20 Henry Howe, op. cit., 1896,

Vol. II, p. 59.

21 Ibid.

158

Ohio Arch. and Hist. Society Publications

Kentucky and West Virginia to the

furnace regions of

the county. The constant moving about,

and the asso-

ciation of the Jackson Countians with

the inhabitants

of the river cities, brought about new

modes of living,

and improved means of manufacture. Soon

the one-

room cabins gave way to more modern

dwellings. Dur-

ing the year 1817 the town of Jackson

was incorporated,

and the community at large began to

take on new life.

The migrations of persons from Lawrence

and

Scioto Counties into Jackson County

served a good

purpose, when a new furnace was

projected in 1848.

This second venture in the county was

promoted by

John Campbell,22 the

well-known furnace man of Law-

rence County. Many of the residents of

Keystone and

the neighboring villages, had served

apprenticeships

under Campbell, and thus was provided

experienced

labor for the project. This new

furnace, the "Key-

stone," was to be located on

Raccoon Creek, and it was

planned to make use of the creek for

transportation.

The attention of the community was

drawn to the

lack of suitable transportation

facilities, by the promo-

tion of this second furnace. A

corporation was there-

fore organized for the purpose of

making the creek nav-

igable for travel. "The Raccoon

Navigation Company"

consisted of James Riggs, Nicholas

Thevenin, Alexander

Williams, James Lewis, Charles Giles,

Joseph S. Coombs,

A. Bentley, and Moses R. Matthews. It

was incorpo-

rated February 4, 1848, with a capital

stock of $100,000.

The commissioners of Gallia, Jackson,

and Athens

22 Howe stated:

"To no other individual is so much due for developing

the resources of 'Hanging Rock Iron

Region.'" Henry Howe, op. cit., 1896,

Vol. II, p. 63.

|

The Jackson County Iron Industry 159 Counties were authorized to subscribe to the said stock, any amount not to exceed $20,000 each. The survey completed, the work was begun, but the possibility of a railroad killed the enterprise.23 In like manner experiments were made on the west- ern boundaries of the county, to determine the practic- ability of using the Scioto River for traffic. During the winter of 1847-48 several steamers began to carry |

|

|

|

on trade along the river going from Portsmouth to Waverly. The last steamer attempting to make it a paying business was launched in October, 1860, and it continued to make trips until 1861. This steamer was called the Piketon Belle. Navigation of the Scioto never passed beyond the experimental stage. Undaunted by failures to navigate the Scioto and Raccoon, Campbell went ahead with the "Keystone" project. The furnace was erected in 1848 by John Mc- Connell and Company, and the stack was 34 feet high, 23 D. W. Williams, op. cit., p. 167. |

160

Ohio Arch. and Hist. Society Publications

being built in the side of a sandstone

cliff.24 The fur-

nace was somewhat more productive than

the first fur-

nace to be built in the county, and

produced from eight

to ten tons of hot-blast iron a day.

The iron was loaded

on rafts, which were built of heavy

logs; the whole out-

fit was then floated down the creek

during the spring

freshets to the Ohio River, and thence

to Cincinnati.

The method proved quite hazardous owing

to the mill

dams, where several men were drowned in

attempting

to get the rafts over the incline. This

plan of shipment

was soon abandoned, and the iron was

hauled to the

Ohio River, although it was about

twenty-five miles

away.

Shortly after the furnace began,

quantities of flint

were found in the ore, and many of the

stockholders

sold out. Their fear proved groundless,

as "Keystone"

became one of the most successful

furnaces in the

county. It passed into the hands of

Green, Benner and

Company in 1853, and they operated it

for many years,

it being one of the last to close down.

"Keystone" like many other

furnaces of the region

in early days never ran on Sundays.

This custom of

closing on Sundays was begun by Robert

Hamilton at

Pine Grove Furnace on December 20,

1844, and fur-

nished a valuable precedent for others.25

In Europe it

was common for the furnaces to be

rested on Sundays,

one famous manager stating "We do

not claim to make

as much iron in six days as we could in

seven, but in the

long run, Sabbath-keeping furnaces make

more in a year

than those which do not rest."26

24 See appendix for complete statistics

on this furnace.

25 E. B. Willard, op. cit., Vol.

I, p. 271.

26 Journal U. S. Association Charcoal

Iron Workers, October, 1884.

The Jackson County Iron Industry 161

During the year 1851, a third furnace

was projected

in the county, the "Buckeye,"

which was located only

a few miles north of

"Keystone." It differed but little

from the other furnaces in the county.

The stack was 37

feet high, and it produced from 10 to

12 tons a day. It

was built in the side of a cliff, the

opening being plainly

visible in the center. The company

purchased 4,500

acres of land about the furnace, and

employed the firm of

Newkirk, Daniels & Co. to erect the

plant, a hot-blast

stack.

Relative to the merits of hot-blast vs.

cold-blast iron,

as produced by the various furnaces in

1850, the fol-

lowing quotation is of particular

value:

Most ores, when smelted with cold blast,

will make an iron

which will have a more uniform and

lasting chill than when

smelted with hot blast. Some ores are

affected more injuriously

than others. Some, when smelted with hot

blast, make an iron

not better than the average of

anthracite iron. We know of no

red or brown hematite ores, which will

not make a better iron

when smelted with cold blast.27

The following query also brings out the

fact that

charcoal iron was considered more

valuable for cast-

ings than other irons, different

factors being equal.

The Lobdell Car-Wheel Company of

Wilmington, Del-

aware, was asked what advantages

charcoal pig iron

possessed over other fuels for chilled

castings, with the

following result:

All of our wheels are made of a mixture

of different kinds

of charcoal iron. We suppose that a

reasonably good wheel

could be made of a mixture of other

fuels, but a better one

could be made of charcoal iron. Wheels

made of iron smelted

27 Journal U. S. Association Charcoal

Iron Workers, 1882-1883. Re-

port of Lobdell Car-Wheel Co.,

Wilmington, Del.

Vol. XLII--11

162

Ohio Arch. and Hist. Society Publications

with charcoal will have a more uniform

and lasting chill than

if the ore is smelted with anthracite

coal or coke. We know of

no wheel that is equal to a good chilled

cast-iron wheel, made

with proper care and of the proper

material, if safety and

economy are considered.27a

Following the establishment of the

Hocking and

Scioto Railroad in 1852-53, several new

markets were

created for iron, and the industry

received a great

impetus. "Keystone" hauled no

more iron to the Ohio

River, but brought its iron to the

railroad at Keystone

Station, and to Jackson, where it was

shipped to its

destination. The larger amount of the

hauling was

done in the summer, when the roads were

in a more

passable condition. The greatest iron

market for the

three furnaces in the county was in

Pittsburgh, although

Wheeling, Cincinnati, and Marietta

received large ship-

ments.

The town of Jackson itself used a small

amount of

the iron produced by the furnaces, in

its two foundries.

The Jackson Foundries and Machine Shop

was founded

in 1847, at a cost of about $10,000. It

made hot-blast

car-wheels, and all kinds of castings,

especially desir-

able for furnace equipment. It employed

about a half-

dozen men in the beginning. Three years

later the

"Old Jackson Foundry" was

established. This estab-

lishment manufactured about the same

type of article,

with one exception--they introduced the

cast-iron stove

to the community. Pickrel and Company

built the lat-

ter-named foundry at a cost of about

$11,000.

When the news of the Scioto and Hocking

Valley

Railroad was spread during the early

'fifties, the fur-

naces at once began to stack their iron

along the right of

27a

Ibid.

The Jackson County Iron

Industry 163

way, that they might take advantage of

the first oppor-

tunity. Buckeye Furnace had large stacks of iron piled

up at Jackson, and thus was one of the

railroad's first

customers. Another result of the coming

of the rail-

road was the establishment of the first

bank in the city

of Jackson. People realized that with

new outlets,

commerce would develop, and new

industrial and eco-

nomic changes would be inevitable. The

following

notice appeared in the Jackson Standard,

in August,

1851:

Bennett and Company have established a

bank in Jackson,

and are prepared to loan money on short

time, in large or small

sums, upon approved security, and also

purchase good negotiable

paper and county orders on favorable

terms.

Office for the present over the

Auditor's office.

Bank open from 10:00-12:00 M.

August 7, 1851. J. W. Laird, Cashier.

CHAPTER III

DAWN OF THE RAILROAD

Prior to 1827 all the railroads built

were composed of wooden

rails, and constructed only for the

purpose of carrying heavy

materials very short distances. In 1827 the Baltimore

and Ohio

Railroad was chartered by the Maryland

Legislature, and this

was the first railroad opened for

carrying passengers. It was

opened for travel from Baltimore to Ellicott's Mills, a

distance

of thirteen miles, on May 24, 1830, and

completed to Washington

City on August 25, 1834.28

By the year 1837, when the first

furnace was

operated in Jackson County, there were

only 1497 miles

of railroad in the United States, with

a total of only

9,021 by 1850. When the railroad fever

reached the

"Buckeye State" about 1850,

Jackson County was an

anxious prospect for the "Iron

Horse." Accordingly,

in 1851, promoters were brought to the southern Ohio

counties, to secure subsidies, etc.,

with the expectation

of building a railroad. The County

Commissioners

purchased stock readily, which later

proved to be worth

only about twenty-five cents a bushel

at a paper-mill.

The first Jackson County railroad

project was the

"Iron Railroad." A charter

was issued by special act

of the Legislature, March 17, 1849, and

the capital stock

was fixed at $500,000. Lawrence County

was par-

ticularly interested in this line, as

it would bring the

iron and coal from the northern part of

her boundaries

to the Ohio River. It was proposed to

build a line

from the present site of Ironton, in

Lawrence County,

28 25th Annual Poor's Manual of

Railroads. Pub. about 1890.

(164)

The Jackson County Iron Industry 165

north through Jackson County, and

connect it with the

Marietta and Cincinnati project in

Vinton County. The

necessary capital could not be secured,

and the matter

was dropped for the time being.

Two years later, in March, 1851, the

County Com-

missioners of Jackson County subscribed

$100,000 to

the "Scioto and Hocking Valley

Railroad." An agree-

ment was reached whereby a release was

to be given

upon their contract with the "Iron

Railroad," that the

county might not lose thereby. The

Scioto and Hock-

ing line crossed the Jackson County

boundary line in

May, 1853, and thus became the first

railroad of this

section. The line opened up a new line

of trade to the

north via Columbus, and other northern

points, and

later became a great rival with the

Ohio River route.

It was at first intended that the

"Scioto and Hock-

ing" would be extended to Newark,

Ohio, but the Ma-

rietta and Cincinnati R. R. began a law

suit, which

caused much delay. The road was stopped

at Jackson,

but after a time it was completed to

Hamden, where it

made connections with the M. & C.

R. R., and the

Newark end was abandoned. The right of

way for

these early roads was secured mostly by

easement, and

was one hundred feet wide. The Scioto

and Hocking

Valley road later became the property

of the Baltimore

and Ohio.

Immediately upon receipt of the news of

a railroad,

improvements in marketing facilities

were commenced

and better production was begun. The

old settlement

called Portland, in the southern part

of the county,

literally moved west, the old public

square was aban-

doned, and the buildings were erected

several hundred

166 Ohio Arch. and Hist. Society Publications

feet to the west to be near the

railroad. The new set-

tlement, Oak Hill, was composed of many

Welsh, who

came to the country between the years

1810-20. The

city of Jackson benefited more than any

other part of

the county. Churches and schools were

built, and

more than one hundred different types

of buildings were

erected between April 1, 1853 and

November 1, 1855.20

During the year 1853 the Scioto Furnace

Company,

also known as Robinson, Glidden &

Co., established the

house of Peter Powell & Co. at Oak

Hill. Its purpose

was to sell goods, and buy iron ore for

Scioto Furnace,

which was located in Lawrence County.30

In addition

to the Scioto Furnace agents, other

furnaces gradually

established agencies for securing ore

and charcoal, and

it is regrettable that so much material

was taken from

the county to be manufactured

elsewhere.

The impetus given to business by the

first railroad

soon led to the establishment of

another. The Marietta

and Cincinnati Railroad was extended to

Byer in the

north-western part of the county on

June 4, 1854.31

Coach lines were then established

between Byer and

Jackson, in addition to the existing

lines running be-

tween Jackson, Chillicothe and

Gallipolis. This stage

line between the latter cities left

Gallipolis on Tuesdays,

Thursdays, and Saturdays, at 4 A. M.,

and arrived at

Jackson at 12:15 P. M., and reached

Chillicothe at 8:00

29 E.

B. Willard, op. cit., Vol. I, p. 457.

30 "The

Scioto Furnace Co. bought one acre of land from James

Kennedy a quarter of a mile west of

Cackley's Switch for $120. It was on

top of a hill, and the dirt was plowed

and stripped down, the ore on the en-

tire acre was taken out. It yielded a

little over 4,000 tons of good ore.

This is a fair average for that region,

and shows that the lands are cheap

at $2,000 an acre"--Davis Mackley.

Article in Jackson Standard about 1860.

31 E.

B. Willard, op. cit., v. I, p. 459.

The Jackson County Iron

Industry 167

P. M., the total distance between

Gallipolis and Chilli-

cothe being about sixty-five miles.

The three furnaces which were in

operation when the

railroad was completed in 1853-54, were

"Keystone,"

"Buckeye," and

"Jackson." These furnaces rapidly

made plans to expand their business,

and felt much more

confident as to the future of the

industry. The firm of

Green, Benner & Co. assumed the

management of Key-

stone Furnace, in 1853, and greatly

expanded the hold-

ings. Jackson Furnace, under the

control of Ellison,

Tewksberry & Co. was now enabled to

load their iron

at a nearby point. As has been stated

already Buckeye

Furnace had large stacks of iron at

Jackson, awaiting

the coming of the first train. This

iron was soon on its

way to Columbus, Cincinnati, and

Chicago. The cold-

blast iron was selling at thirty to

forty dollars a ton,

and was greatly in demand.

When the Scioto and Hocking Valley road

was com-

pleted to Hamden in 1855, giving a

direct route to Cin-

cinnati, six furnace projects were

begun. The Iron

Valley (later the Cornelia, and still

later the Lincoln)

was built in 1854, by Thompson, Laslie

& Co. at a cost

of $115,000. The company purchased 5,000

acres of

land in the immediate vicinity. The

Lincoln Furnace

was constructed somewhat differently

from the others,

in that a part of the stack was hewn

from the solid

stone of the cliff of which it was a

part, and the blast

was sent through a tunnel driven

through the rock in

the same manner. An interview with an

old resident

of the vicinity, Mr. Sent Thorn,

developed that he re-

membered having seen the ox-teams

dragging the heavy

loads of iron over the hill, following

the creek valley

168 Ohio Arch. and Hist.

Society Publications

for a short distance, to the loading

place at Hamden

Junction, about six miles away. Mr.

Thorn stated that

the roads were practically impassable

during the winter,

and that most of the hauling was done

in the spring

and summer. About the time of the Civil

War, a

branch line of the railroad was

constructed to a point

within a few miles of the furnace, and

this aided mate-

rially in its growth.

Latrobe Furnace was built in 1854, a

few miles to

the southeast of Berlin. The capital

stock of "Latrobe"

was $60,000, and the company was

composed of William

McGhee, H. S. Bundy, H. F. Austin, and

R. C. Hoff-

man of Jackson County, and V. B. Horton

of Pomeroy.32

Block and kidney ore were both found in

abundance on

the company's land, the latter being

extensively used.

Limestone was also available, as well

as coal for use in

firing the boilers.

Madison Furnace, also erected in 1854,

was in the

center of vast ore deposits. Portsmouth

capital was

largely instrumental in building this

furnace, backed

by Mr. John Campbell, veteran furnace

man. Madi-

son's product was largely disposed of

in Portsmouth

during her first few years of

operation. The first

shipment of iron was in July, 1854,

from the siding at

Cross Roads, about three miles from the

furnace.33

It is regrettable that the same

conditions did not

exist at the time of the completion of

this group of

furnaces, as existed the year before

(1854). Iron

which sold for $50.00 in 1853, sold for

$35.00 in 1854.

All business except farming began to

lag, and prac-

32 E. B. Willard, op cit., v. I,

p. 455.

33 Feature

article, Jackson Herald, January 1900.

The Jackson County Iron Industry 169

tically all the furnaces which had been

erected were

unable to run, due to lack of funds.

The persons who

had swarmed to the county with the

prospect of the

railroad and the iron industry, now

began to go else-

where, and this migration continued for

several years.34

The largest of the group of six

furnaces erected in

1854, was the "Monroe,"

organized under the name of

the Union Iron Co. The same group also

owned the

Madison Furnace, and the Washington

Furnace, which

was, however, across the county line in

Lawrence

County. Colonel Wm. M. Bolles, a nephew

of Profes-

sor William Mather, the first State

geologist, was in

active control of Monroe Furnace. It

made an average

of eighteen tons a day, as contrasted

with twelve and

fourteen tons, the capacity of its

competitors.35 Cam-

bria Furnace was built by a group of

Welshmen, on a

site which is now called Black Fork. It

was incorpo-

rated by David H. Lewis & Co. Many of the Welsh

settlers traded their homes, land and

belongings for a

share of stock. Practically all of the

timber-land was

secured by this method. Thomas M. Jones

was one of

the first managers of

"Cambria," and he proved to be

quite successful.36

The most successful, as well as the

best-known fur-

nace established at the beginning of

the railroad era in

1853-54, was the Jefferson Furnace. It

was erected

34 "A relative of E. D.

Ricker, living in New England, came over to

Madison Furnace in a sleigh during the

big snow of 1856, an incident which

illuminates the conditions prevailing in

the '50's."--E. B. Willard, op. cit.,

Vol. I, p. 455.

35 See appendix for sizes various

furnaces.

36 The iron from this furnace was hauled

over the hills to Gallia

Landing, the first railway stations

being termed "Landings," by the river

men.

|

170 Ohio Arch. and Hist. Society Publications by a company of Welshmen, who had become dissatis- fied with their connections at Madison Furnace.37 The barren, bleak and heavily wooded hills of that part of the country hid a wealth of rich limestone ore that was almost self-fluxing. The following quotation is very descriptive of the foundation of Jefferson Furnace: |

|

|

|

A joint-stock company was organized in January, 1854, under the leadership of Thomas T. Jones, David Edwards, et al, all Welsh, the capital being $50,000, and divided into shares of $500.00 each. Many of these stockholders traded land to the company in exchange for stock, some giving as much as 160 acres at $12.00 an acre, reserving the land where their buildings stood, and the right to cultivate what had already been cleared. Some of the less fortunate persons offered to allow their accu- mulated wages to be applied as part payment for stock. Although the company had a large amount of paid-in capital, it was neces- sary to go into debt considerably to build their plant. The firm had in the beginning 2,000 acres of timber-land, valued at $24,000, 37 Interview with Andrew J. Dutiel, last Madison Furnace manager, 1931. |

|

The Jackson County Iron Industry 171 and cash to the value of $26,000 fully paid. A peculiar statement in their constitution provided that none but persons of Welsh birth could hold stock, and that the furnace should be always shut down on Sundays, as was common among other early industrial enterprises.38 Relative to "Jefferson's" beginning, Mr. Jones the last manager of the furnace, states that "The first cast was on October 15, 1854, and in the following winter they made 800 tons of iron, which turned out to |

|

|

|

be of superior quality for car-wheels and machinery. It produced about four or five tons a day in the begin- ning, although in a short time it was casting about ten tons a day.39 In a short time "Jefferson" iron became known as a standard of excellence throughout the Hanging Rock Region. It was sold under the trade name "Anchor." The iron from this furnace was loaded at Oak Hill, 38 Article in Jackson Herald, February 17, 1900. 39 Interview with Joseph J. Jones, last Jefferson manager, 1931. |

172 Ohio Arch. and Hist. Society Publications

three miles away. It was hauled to the

station by large

cumbersome wagons, drawn by three ox

teams. The

haulers worked in two shifts of twelve

hours each, be-

ginning at sunup. Some residents of the

Jefferson

neighborhood have stated that many

mules and oxen

were killed in pulling these heavy

loads of materials up

and down the seemingly impassable

roads. The photo-

graph on page 171 gives a splendid

impression of the

manner in which the hauling was done.

The business depression which began

about 1856, was a great

handicap to industrial growth. So far as

can be determined,

none of the furnaces were making profits

during the years

1856-1860.40

Several of the furnaces were out of

blast for long

periods of time, due to lack of

capital, and surplus

stocks, caused by the general

depression. Jefferson

Furnace suffered along with the others.

"A part of the

company holding about one-third of the

whole stock

contracted the 'Go West' fever and sold

out their in-

terests to the remaining members for

$900.00 a share,

thus nearly doubling their money in two

years' time."

This threw the officers into additional

debt, and they

advertised the furnace for sale about 1860,

but no offer

came, and necessity forced them to make

the best of

things.

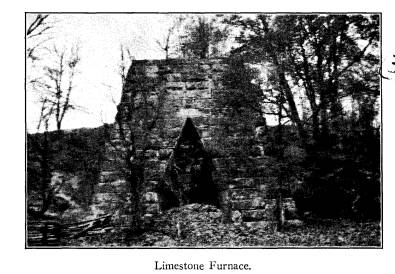

Undismayed by general business

conditions, another

charcoal furnace, "Limestone"

was constructed in 1855.

Splendid workmanship was displayed in

its erection as

is shown in the photograph below.

"Limestone" dif-

40 History of the Lower Scioto

Valley, p. 669. This text further states:

"The policy of Jefferson was to get

all additional timber-land possible, and

save their own for later use. They

sometimes bought the land, then sold it

after they cut the timber off."

|

The Jackson County Iron Industry 173 fered but little from the "Madison," and was located only a few miles north of the latter-named furnace. Although situated in the center of a rich bed of ore, the lack of capital soon made it evident that it would not be a success. The year following its construction, (1856), it was sold to another firm. In 1858 it passed into the hands of a receiver, and by 1860 was out of blast en- |

|

|

|

tirely. The owners were constantly handicapped by lack of capital.41 The following items of interest concerning Lime- stone Furnace were given by an old resident of the neighborhood: John Williams was the foundryman, or the man that "blowed the furnace." The ore was secured chiefly on the Williams farm, only a few miles away. They hauled loads of iron to the siding, and returned with loads of ore. The iron was first hauled to Crossroads Landing, and later to Vinton Switch, as in the latter 41 History of Lower Scioto Valley, p. 497. |

174 Ohio Arch. and Hist. Society Publications

case direct contact was secured with

the Columbus route. As

many as sixteen teams were engaged in hauling during

the sum-

mers, and they were paid about $15.00

per month. Labor re-

ceived 75 cents a day. The charcoal was

secured largely on the

company's land, and the wood-choppers

were paid from 30 to

50 cents a cord for cutting the

necessary wood supply.42

During the year 1854, one year before

the construc-

tion of the last charcoal furnace to be

erected in Jack-

son County, the following article

appeared in the Jack-

son Standard:

We understand that on or about the 20th

inst., there will be

experiments made to bring into use the

Jackson coal for iron

making. The Washington Furnace has made

preparations to test

the matter in full and decided

satisfaction. Much depends upon

the success of this important matter.

If it is possible that our

coal can be used in the manufacture of

iron, Jackson County can

build all the railroads in the State.

Her wealth can be surpassed

only by California. We look with an

anxious eye to the success

of this great and important experiment.43

Unfortunately no statement can be found

relative to

the actual result of the above experiment,

but it was

evidently regarded as a success. Coal

had been mined

in the county since 1823, and it was

used to a great ex-

tent throughout the entire region for

firing the furnace

boilers. It was argued that if raw coal

could be used

in the Mahoning Valley furnaces of

Ohio, and also in

the Shenango Valley furnaces of

Pennsylvania, it was

reasonably expected to be successful

here. At least the

following article appeared in the

Jackson Standard in

1855, which added to the enthusiasm:

Mr. Joseph Crowther has succeeded in

coking or rather

charring Jackson coal, which is in

every sense of the word cal-

culated for furnace use. Our furnace

men say that it will

answer the same purpose as charcoal,

for making iron.

42 Interview with Pat Varley, Wellston,

Ohio, March, 1931.

43 Article in Jackson Standard, March,

1854.

The Jackson County Iron Industry 175

The news of the coal possibilities

brought on another

slight boom, and several projects

resulted therefrom.

The year 1855 brought the first

telegraph-line to the

country, which proved to be a great aid

to communica-

tion. The first daily line of stages

was started from

Jackson to Byer Station, on the

Cincinnati & Marietta

R. R. in July, 1855, thus giving a

daily line to Cincin-

nati.

An attempt was also made to bring another rail-

road into the county, as noted in the

following para-

graph:

This new railroad was to be known as the

"Hillsboro, Jack-

son and Pomeroy." An organization

was effected, and work

begun in 1856, with a number of Jackson

men taking the initiative.

Considerable grading was done, but the

promoters had not con-

sidered the fact that they might be